Your Solution Finder in the Mining Sector

Learn more

LCS Cable Cranes

Innovative

Our QXcrane

Our revolutionary QXcrane is the solution for your challenge to work in inaccessible hazardous terrain in the mining sector. It covers an area of 1000 x 1000 meters. Within this area, workers can safely and quickly reach any location by means of an operator basket. The modular securing system adapts to any terrain situation, no matter how extreme. It is also used in Tailing Dams or at Tailing Storage Facilities (TSF).

- Material transport of up to 500 kg, placeable at any location

- Coverage: 1000 x 1000 m, fully accessible by an operator basket

- Modular design: specific project and terrain adaption

- Safe personnel transport and fast evacuation in case of an emergency

- Operation by one person inside of the operator basket

Tower head

The tower head disposes of a deflection pulley which deflects the driving rope from the driving winch to the operator basket.

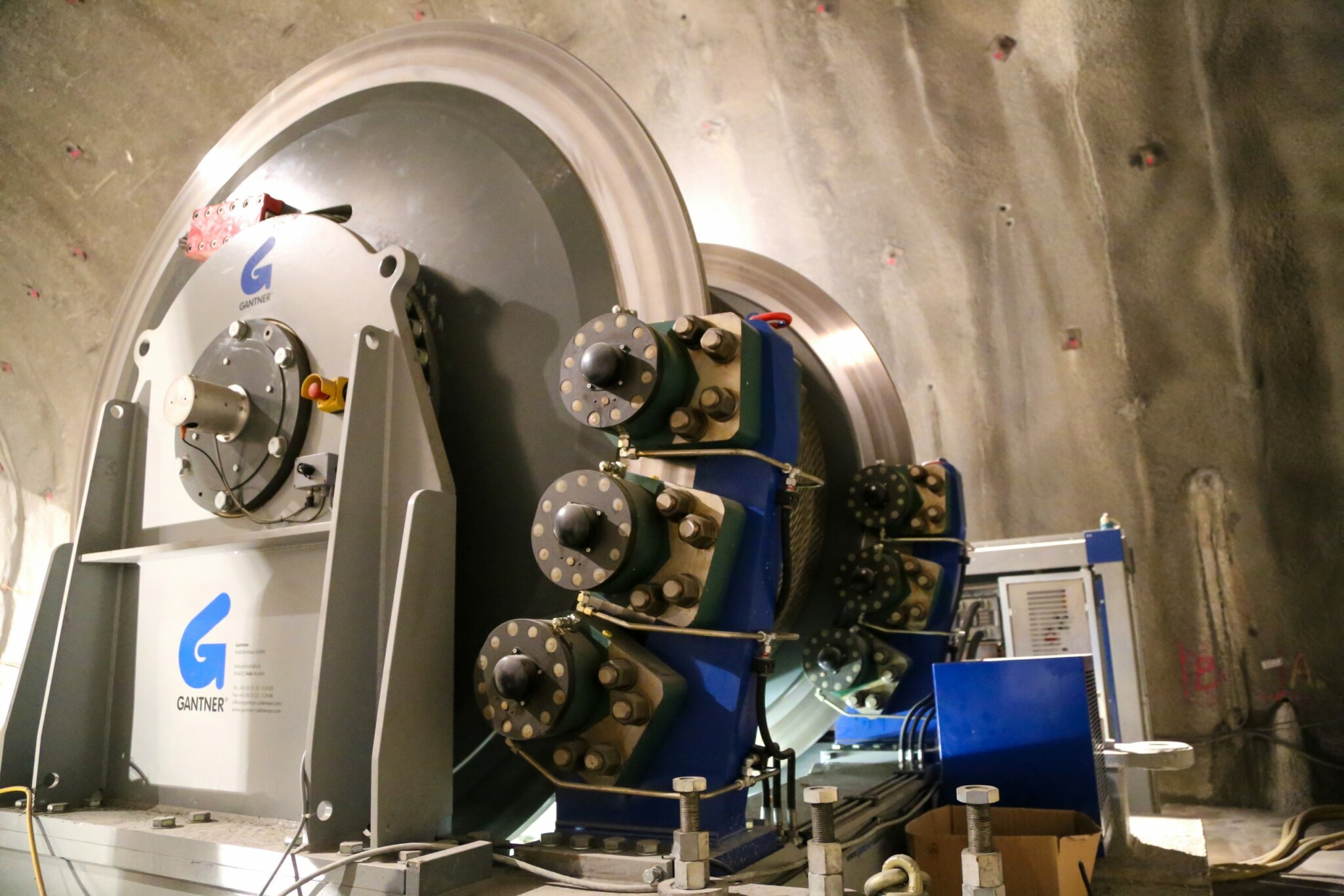

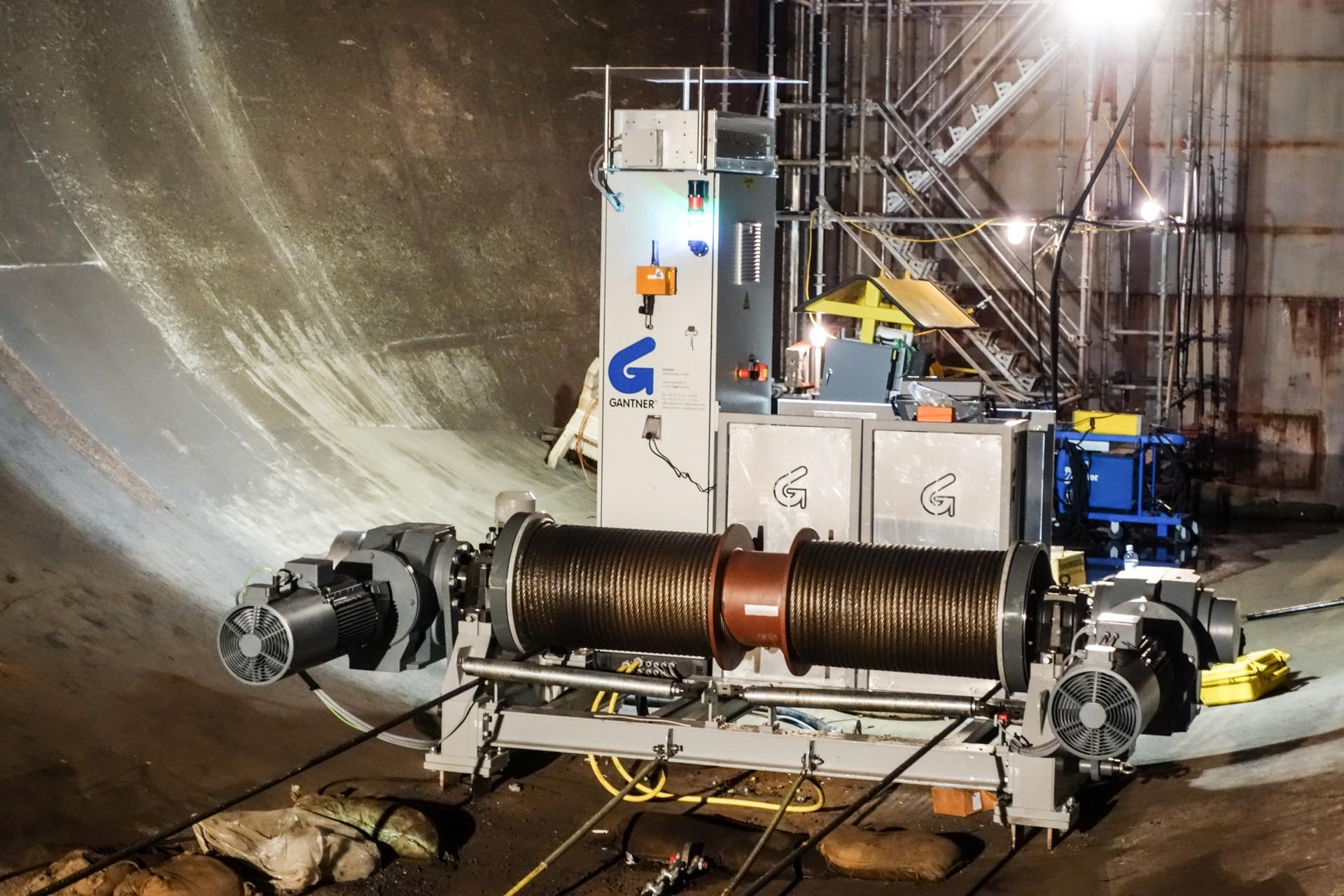

Driving Winch

A driving winch, which is positioned at each tower base, is equipped with a braking resistor and a rope testing device.

Operator basket

The operator basket secures the personnel working in the field by means of hoisting winches. It is also possible to transport material up to 500 kg.

Tower

The tower height can be adapted according to the given terrain due to the modular design of the entire system.

Tower head

The tower head disposes of a deflection pulley which deflects the driving rope from the driving winch to the operator basket.

Driving Winch

A driving winch, which is positioned at each tower base, is equipped with a braking resistor and a rope testing device.

Operator basket

The operator basket secures the personnel working in the field by means of hoisting winches. It is also possible to transport material up to 500 kg.

Tower

The tower height can be adapted according to the given terrain due to the modular design of the entire system.

Our expertise

We develop cable crane and winch solutions for different applications in the mining industry to enable rescue operations, material and personnel transport, and a safe work environment.

Mining sector

Our solutions

Flexible

Our QXcrane-2D

01Our QXcrane-2D provides access to previously inaccessible hazardous terrain: A motorised crane unit moves on a track rope tensioned between two towers. The crane unit can lift and lower a operator basket at any point along the track. Thereby, repairs, inspections and remedial works are carried out along the defined section in an safe and efficient manner. The system adapts to any terrain situation, no matter how extreme, and is suitable for use at Tailing Storage Facilities, for example.

- Material transport of up to 2000 kg

- Access and monitoring of a defined section „from above“

- Modular design: specific project and terrain adaption

- Safe personnel transport and fast evacuation in case of an emergency

- Easy operation and maintenance

Three-dimensional

Our Luffing Tower Cable Crane System (LTCC)

02Our luffing tower cable crane system ensures continuous transport logistics, independent of ambient conditions. By covering three dimensions, a large working area can be reached with just one system. The transport routes between the loading and unloading point are direct, so that a large transport volume can be achieved in a short period of time. Even with poor access to the working area the system can be used without restriction. The system is operated by only one person from the central control station outside the working area.

- Payloads of up to 30 to

- Independent, continuous transport logistics

- Modular design: specific project and terrain adaption

- High travel and working speed

- Low operating costs; costs for road construction are eliminated

Solid

Our Cable Crane System

03When it comes to precise loading and unloading along the entire route and yet high travel and working speeds are required, our cable crane systems are used. They provide the direct connection between loading and unloading point and thus ensure independent continuous transport logistics. Our cable crane systems can also be used in any climatic conditions and are not influenced by the weather pattern.

- Payloads of up to 30 to

- Independent, continuous transport logistics

- Modular design: easy adaption to changing site conditions

- High travel and working speeds

- Low environmental impact in sensitive areas

Customised

Our winches, shaft and rescue winches

04We are specialised in the planning and construction of winches. Thus, we develop a tailor-made solution for every situation. Our portfolio includes winches for the transport of material and personnel, special rescue winches as well as a variety of other different types. We adapt all winches to the applicable national standards. Additional safety functions as well as targeted shut-down and monitoring options can be integrated as a supplement.

- Payload ranges: 10 – 1.000 kN

- Rope capacities of up to 3.000 m

- Customised solutions

- Suitable for inclined or vertical shafts

- Specifically tailored to national standards and project requirements